As a pioneer in carbon fiber application technology, McLaren has been pushing the limits of lightweighting and performance with more than 40 years of experience in racing and mass-produced cars. Now, the brand has once again set a global precedent by bringing carbon fiber manufacturing technology originally used in the aviation industry into the automotive field for the first time, officially launching the revolutionary "McLaren ART Carbon Fiber" (Automated Rapid Tape), setting a new milestone for supercar engineering. McLaren ART carbon fiber technology is based on the structural manufacturing method of the latest generation of jets and fighters in the aerospace industry. Different from the traditional production method of manually laying pre-preg carbon fibre, the aviation industry has begun to use robotic arms to automatically and precisely stack composite tapes to manufacture wing and fuselage structures in recent years, greatly improving accuracy and efficiency. McLaren's breakthrough "Automated Rapid Tape" technology further uses a fixed composite deposition head with a platform that can move and rotate quickly, successfully greatly improving production speed, accuracy and mass production feasibility, and truly realizing high-efficiency industrial mass production of supercar carbon fiber structures.

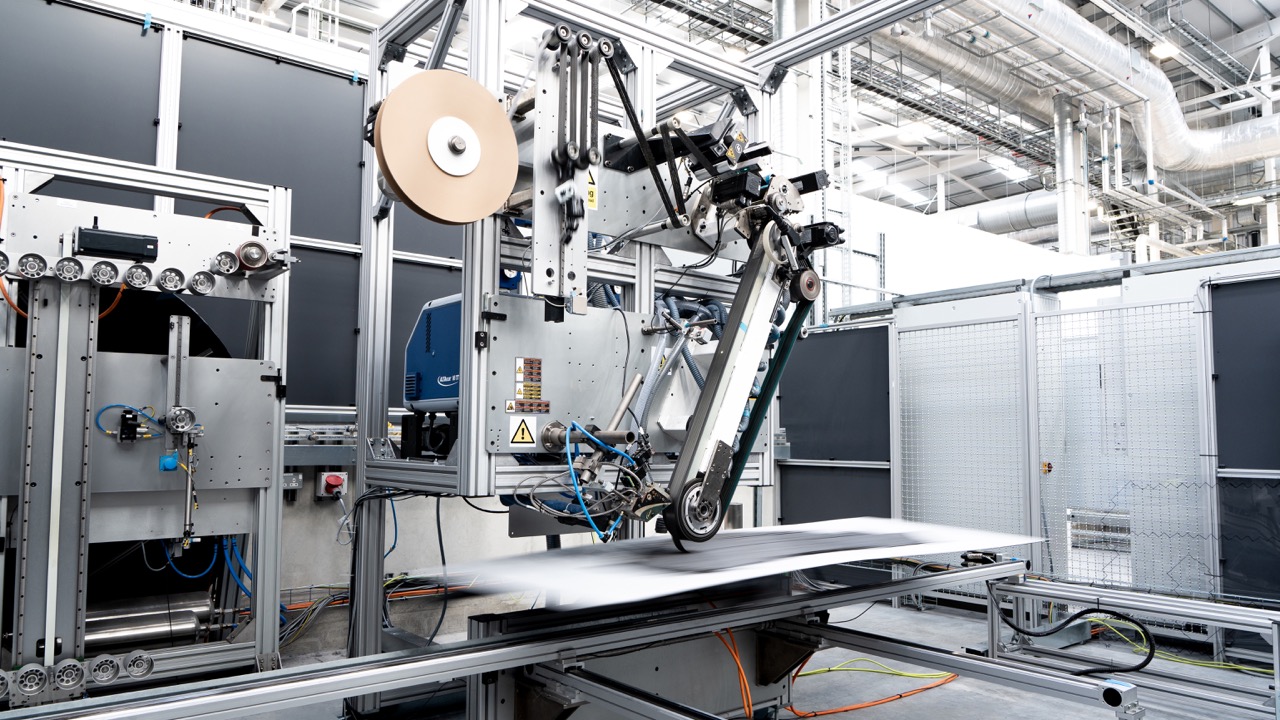

McLaren ART carbon fiber technology is based on the structural manufacturing method of the latest generation of jets and fighters in the aerospace industry. Different from the traditional production method of manually laying pre-preg carbon fibre, the aviation industry has begun to use robotic arms to automatically and precisely stack composite tapes to manufacture wing and fuselage structures in recent years, greatly improving accuracy and efficiency. McLaren's breakthrough "Automated Rapid Tape" technology further uses a fixed composite deposition head with a platform that can move and rotate quickly, successfully greatly improving production speed, accuracy and mass production feasibility, and truly realizing high-efficiency industrial mass production of supercar carbon fiber structures.

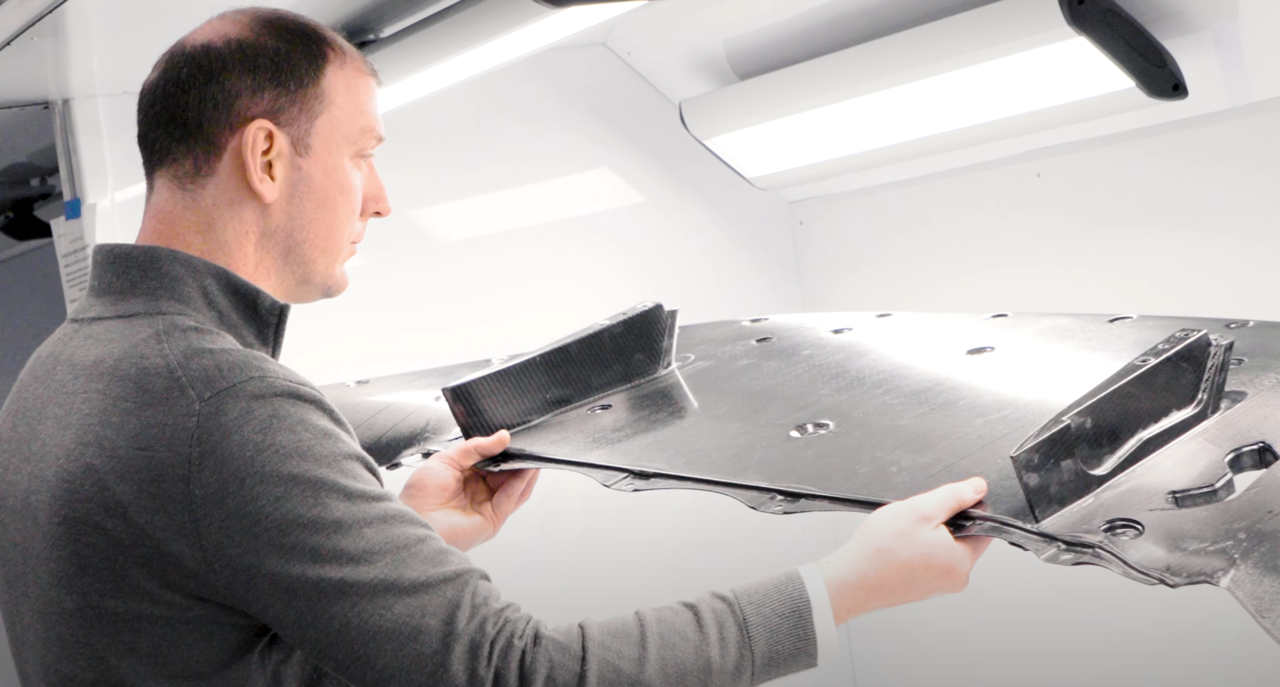

This innovative technology brings many unprecedented advantages. First, engineers can freely adjust the arrangement direction of the fibers, so that the material can achieve extreme rigidity in specific areas while retaining appropriate elasticity in other parts, completely breaking through the design limitations of traditional carbon fiber materials. By precisely adjusting the fiber layout, the weight distribution of the material can be optimized, especially the fibers can be concentrated at the connection points, edges and joints with the greatest force, while other low-force areas can significantly reduce the material consumption, further strengthening the ultimate balance of "lightweight and high strength" to create a higher performance and more efficient structure. ART carbon fiber significantly reduces the amount of waste generated during the production process, and up to 95% of the carbon fiber material can be directly used in the final structure, greatly improving production efficiency. Because it is automated production, it can ensure that each part can achieve extreme precision, reduce material loss caused by manual errors, and further ensure the consistency of product quality.

ART carbon fiber significantly reduces the amount of waste generated during the production process, and up to 95% of the carbon fiber material can be directly used in the final structure, greatly improving production efficiency. Because it is automated production, it can ensure that each part can achieve extreme precision, reduce material loss caused by manual errors, and further ensure the consistency of product quality.

Another major advantage of this innovative production method is that it greatly reduces the manufacturing time and cost of carbon fiber parts, which means that McLaren will be able to apply carbon fiber to more body and structural parts on a larger scale in the future. This will completely change the supercar industry's imagination of the application of carbon fiber materials, no longer limited to the chassis or structural core, but more widely extended to all levels of the entire vehicle. In fact, this technology is not a future concept, but an active technology that McLaren has put into use. The brand's McLaren Composites Technology Centre (MCTC) in Sheffield, UK, has officially installed the ART carbon fiber prototype mass production unit, and will officially expand into an industrial-grade production line in 2025, greatly improving mass production capacity and truly realizing large-scale industrial production of top-grade carbon fiber parts.

In fact, this technology is not a future concept, but an active technology that McLaren has put into use. The brand's McLaren Composites Technology Centre (MCTC) in Sheffield, UK, has officially installed the ART carbon fiber prototype mass production unit, and will officially expand into an industrial-grade production line in 2025, greatly improving mass production capacity and truly realizing large-scale industrial production of top-grade carbon fiber parts.

McLaren's first mass-produced model to use ART carbon fiber technology is the brand's upcoming ultimate supercar McLaren W1, which is equipped with an active front spoiler fixed wing made of ART carbon fiber. Due to the use of ART technology, its rigidity is about 10% higher than that of traditional prepreg materials, which is a very significant performance improvement for the front wing structure responsible for generating up to 1,000 kg of downforce. In the future, McLaren also plans to apply ART carbon fiber technology to more W1 mass-produced parts. Looking to the future, the birth of McLaren ART carbon fiber provides unlimited possibilities for the brand's next-generation supercar architecture. The brand also plans to use this revolutionary technology to develop the next generation of ultra-lightweight carbon fiber chassis structures that are lighter, stronger and more efficient, truly defining the standards for future supercars.

Looking to the future, the birth of McLaren ART carbon fiber provides unlimited possibilities for the brand's next-generation supercar architecture. The brand also plans to use this revolutionary technology to develop the next generation of ultra-lightweight carbon fiber chassis structures that are lighter, stronger and more efficient, truly defining the standards for future supercars. It is an exciting automotive engineering breakthrough to see McLaren successfully transform high-end carbon fiber production technology from the aerospace field into mass production of supercars. This not only proves McLaren's leadership in carbon fiber lightweight technology, but also shows the brand's determination to continuously innovate and pursue ultimate performance. I firmly believe that with the mass production and popularization of ART carbon fiber technology, McLaren's future products will be able to completely rewrite the standards of the top supercar market with more extreme performance and higher value.

It is an exciting automotive engineering breakthrough to see McLaren successfully transform high-end carbon fiber production technology from the aerospace field into mass production of supercars. This not only proves McLaren's leadership in carbon fiber lightweight technology, but also shows the brand's determination to continuously innovate and pursue ultimate performance. I firmly believe that with the mass production and popularization of ART carbon fiber technology, McLaren's future products will be able to completely rewrite the standards of the top supercar market with more extreme performance and higher value.

Categories: vehicles