In the past, experts have relied on experience and intuition to evaluate whether a car is comfortable to drive, but now there are more scientific and efficient solutions for this task. Porsche Engineering has recently developed a driving comfort evaluation system based on artificial intelligence (AI). Through precision sensors and neural network technology, it provides objective and consistent analysis results, which will greatly accelerate the vehicle chassis development and tuning process. It is also expected to be introduced into mass-produced models to realize the vision of vehicle self-monitoring and real-time adjustment. The development team first used precision sensors to collect a large amount of chassis dynamic data at Porsche's test site in Weissach, Germany, and at the same time cooperated with professional engineers to conduct subjective scoring. After many experiments, these data and scoring data are input into the neural network for learning and training, and finally AI is used to accurately evaluate comfort.

The development team first used precision sensors to collect a large amount of chassis dynamic data at Porsche's test site in Weissach, Germany, and at the same time cooperated with professional engineers to conduct subjective scoring. After many experiments, these data and scoring data are input into the neural network for learning and training, and finally AI is used to accurately evaluate comfort.

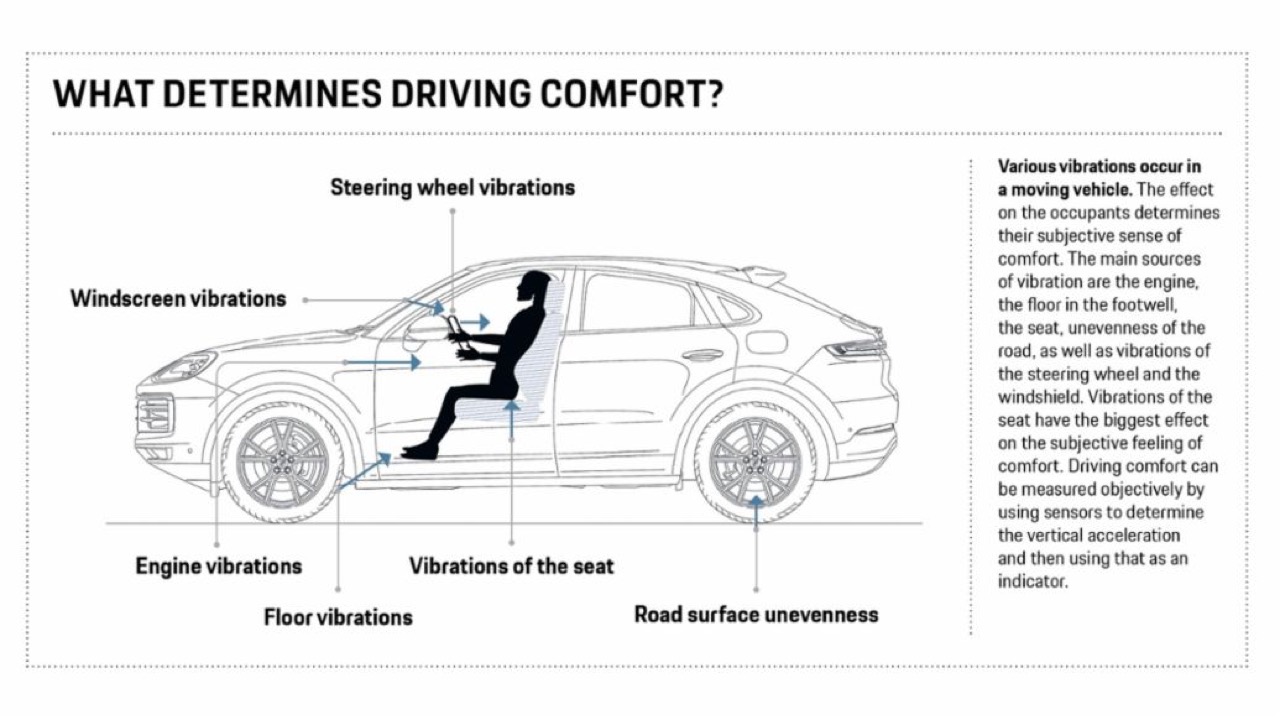

Porsche engineers emphasized that each new car will undergo multiple driving comfort tests before it is launched, from vertical body vibration, side tilt, tire bounce to the reaction when encountering potholes, all need to be repeatedly verified. However, due to the difference in human subjective feelings due to personal preferences and driving experience, there are often slight differences in evalua

tion and lack of objective standards. Therefore, the AI evaluation system is used to assist in objective quantitative analysis, which will become an important auxiliary tool for future chassis tuning.

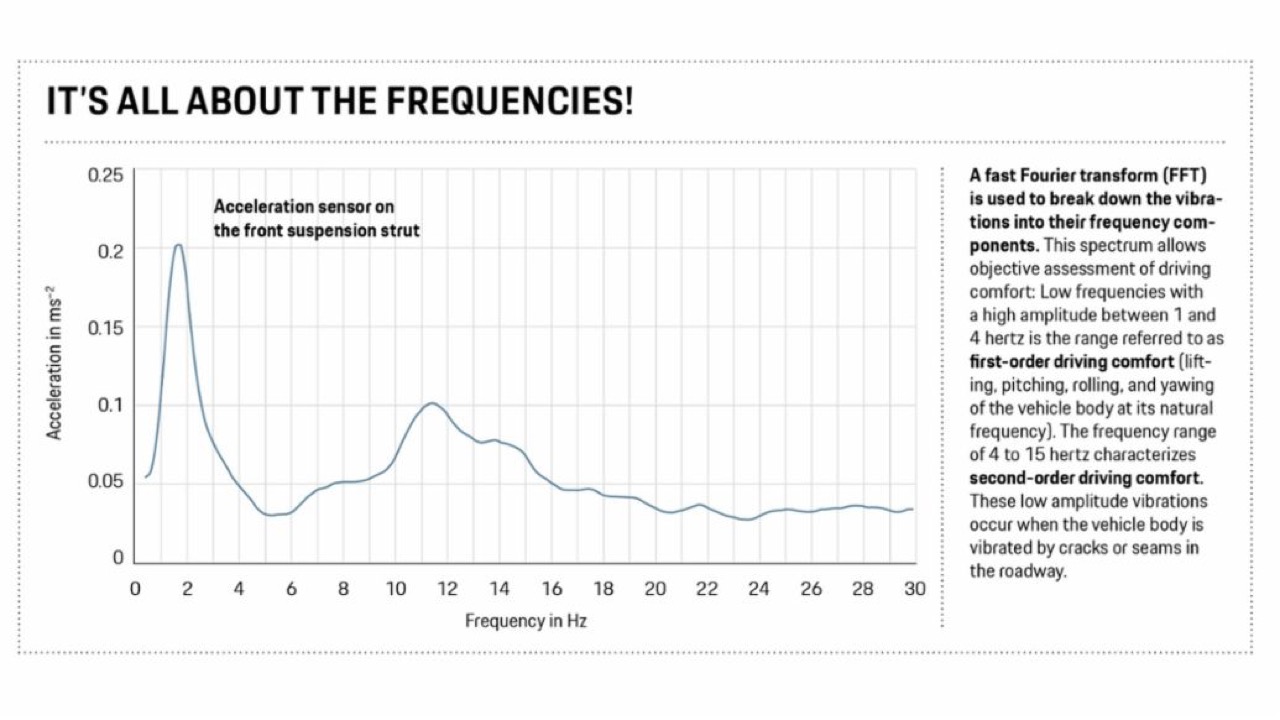

To improve practical applicability, researchers further optimized the sensor configuration, reducing the original six expensive and complex high-precision acceleration sensors to four low-cost, easy-to-install racing-grade sensors, and proved that they can still maintain high accuracy. The AI system only takes one day to train, and it only takes a few minutes to complete a single test analysis, which greatly improves the evaluation efficiency.

In the future, this AI system can not only assist engineers in quickly adjusting the chassis during the development stage of new cars, but also be applied to automated test equipment to optimize automatic chassis parameters by repeatedly simulating specific sections of the road. In addition, what is even more exciting is that this system may also be installed in mass-produced vehicles in the future to monitor the chassis status and driving comfort in real time, becoming an intelligent partner in daily driving and ensuring that users enjoy a stable and safe driving experience. This innovation of Porsche Engineering not only solves the subjective problem of previous comfort evaluation, but also greatly shortens the chassis development cycle. If it can be further integrated into mass-produced vehicles in the future, it will effectively improve the quality of the vehicle and customer satisfaction, and may even open a new chapter in the next wave of automotive intelligence and personalization development.

This innovation of Porsche Engineering not only solves the subjective problem of previous comfort evaluation, but also greatly shortens the chassis development cycle. If it can be further integrated into mass-produced vehicles in the future, it will effectively improve the quality of the vehicle and customer satisfaction, and may even open a new chapter in the next wave of automotive intelligence and personalization development.

Categories: vehicles